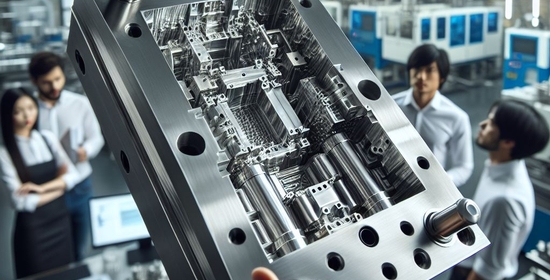

Injection Mold Design and Manufacturing

We have the ability to specify and manufacture the most suitable and complex injection molding tools for our clients, whether they require tools for pre-production, low volumes, large production series, or high-speed multi-cavity tools.

With years of experience, our experts and tool design partners ensure that your injection molding tools will be of the highest quality for a competitive price, based on the client’s budget and usability.

- Trusted Partners: We work with selected local and international partners to provide the most suitable mold for our clients’ needs.

- Mold Maintenance: Throughout the tool’s lifecycle, we provide regular maintenance for all injection molds produced by us or our partners, ensuring that your initial investment is protected and downtime is minimized.

- Moldflow Analysis: We perform Moldflow analyses on existing and developing designs to optimize part filling and strengthen the design component choices.

- Mold Management: We manage over 120 molds in-house.

- Spare Parts Management: We maintain a stock of spare parts to prevent production downtime due to tool issues.

- Robotics Integration: Integration of robotics from the initial design stage.